|

|

|

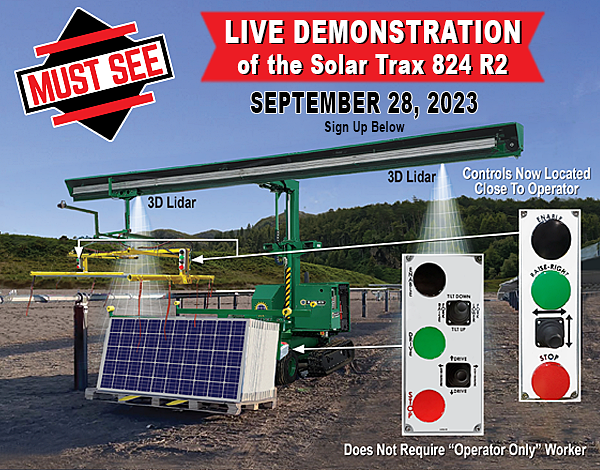

The New Solar Trax 824 Revision 2 Designed for a Three-Man Crew |

|

| Primarily push-button controls, allowing the workers to focus on installing the

panels, while the machinery precisely positions the panels in place. |

|

|

Solar panel installation robot is the first production robot in the field installing solar panels. This is not a concept or a research project.

This is an actual working robot in the field today! |

|

|

Drawing from many years of custom design lift equipment, the Solar Trax is the result of a several year effort, starting with our glass lifting Brandon Trax machine. Developing advanced products, such as aircraft assembly robots for Boeing, spacecraft clean-room machines for Northrop Grumman, to explosion-proof lifts used by the United States Air Force, we are proud to add the Solar Trax 824 to our line of successfully developed leading edge products. |

|

|

|

|

|

|

The Solar Trax 824 will lift panels 8’ high and traverse 24’ to handle most Solar Field designs. The base machine is track driven, providing the highest degree of traction and terrainability. Designed for rough terrains and increased slopes, the upper assembly will automatically level itself for increased stability and ease of panel placement.

All hydraulic functions include Programmed Motion which combines multiple steps, such as “Raise-Left,” which raises the panels from the center position, trolleys sideways to the support frame and lowers it in place. Similar functions include “Home,” which returns the tray to the center position for reload and “Drive-Increment,” which drives the machine forward the exact distance for installation of the next 4 panels.

Incorporating Vision systems from the autonomous vehicle industry allows for precisely locating the solar panels onto the mounting structure. |

|

|

|

|

|

|

The Pallet Management Vehicle (PMV) is used to bridge from current technology with 30 panel pallets located every 50’ to a delivery vehicle that retrieves the panels autonomously. Therefore, it can be used seamlessly with the current worker-based installations to reduce worker fatigue and increase throughput. The PMV is tethered to the base machine. It lifts and tilts a pallet up to 3000 lbs. and is self-propelled. The top of the PMV is a landing support for the tray where panels are easily loaded. |

|

|

|

|

|

|

|

|

|

|

Location:

S81W18561 Gemini Drive

Muskego, Wisconsin 53150

For those that attend the demonstration in Muskego, there will be a follow up demonstration at a solar installation site, TBD.

|

|

|

|

|

|

|

|

|

|

Other Products From Bailey |

|

|

|

|

|

|

Bailey Lifters In Action |

|

|

|

|

|

|